FOR ESBE, THE MIXING VALVE IS WHAT FLOUR IS TO BREAD

2022-10-11

Johan August Skogsfors was a curious man, eager for new ideas and new technology. He decided to dig out the foundation and build a cellar under the dwelling house. In the basement, he placed a wood-fired boiler and through piping and connections, he and his family gained access to both central heating and running hot water as early as 1932. This was the starting point for ESBE’s focus on plumbing products.

ESBE was not the first in Sweden to manufacture mixing valves, but right from the start the sturdy cast iron valves became known for their durability. One of the first mixing valves for example, did its job from 1935 to 1995 (60 years)!

The mixing valve Fyrix sees the light of day, 1939–1949

During the 1930s and 1940s, ESBE’s mixing valves were called 3-way Model 100 and 4-way Model 200. In 1947, a new patented 4-way valve was launched to replace the Model 200. The new valve was named Fyrix and this valve enabled circulation in the boiler circuit as well when the valve was closed to the radiators. A technology that still forms the basis of today’s modern ESBE valves.

At the end of the Second World War, the need for new and improved housing was enormous throughout Europe and ESBE’s mixing valves set the standard for what a mixing valve should look like.

Exciting collaborations helped ESBE, 1950–1969

Now more than the Swedes began to get their eyes on the advantages of the mixing valve. Exports increased steadily and soon reached the whole of Northern Europe. More and more households replaced the wood with the new fuel alternative of the time – oil. At this time, ESBE started several exciting collaborations. Billman Regulator and Tour Agents (TA) were market leaders in Europe. ESBE was commissioned to develop assembly kits so that Billman’s actuators could be mounted on ESBE valves. These assembly kits also became popular with other controller companies. Many wanted the mixing valves from Reftele, in southern Sweden.

More and more oil boilers were equipped with factory-fitted mixing valves and ESBE launched a new type of mixing valve to meet the market’s needs. The valve was named Front and it quickly became a favorite for almost all Swedish boiler manufacturers.

During the 1960s, the Front mixing valve helped spreading the ESBE brand. The Netherlands, France, Switzerland and Austria became new markets and the export share rose to 60 percent.

ESBE’s results in 1969 with 130,000 mixing valves sold placed the company among the leading manufacturers in Europe.

Design created competitive advantage, 1970s

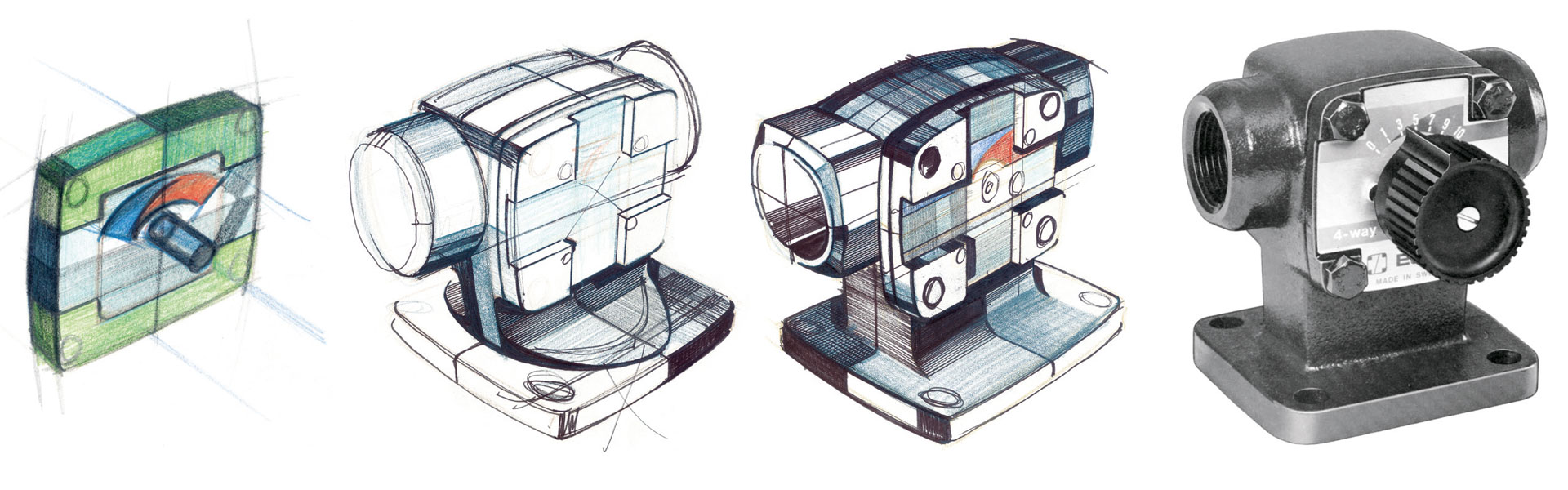

A newly hired production manager, Kurt Hernod, had the opinion that ESBE’s mixing valves looked old-fashioned. He came from the lighting industry and wanted the already popular valves to have a neater and more modern look. ESBE chose to contact one of the most prominent industrial designers of the time, Carl-Arne Breger.

Expensive with design you might spontaneously think, but when Breger’s sketches had been reworked to fit ESBE’s production, it turned out that the designed products cost less to manufacture compared to the previous ones. The tooling costs quickly paid for themselves and also had the positive effect of making all the ESBE copies on the market look hopelessly ancient.

During the 1970s, it was time for yet another energy transition. The oil crisis caused interest to increase in new heat sources such as direct-acting electricity, heat pumps and solar energy. The tried-and-tested wood fired boiler was also in the spotlight again. All in all, this meant that the mixing valve was joined by new products; ESBE mixing valve TB 20 and ESBE draft regulator C20. ESBE also developed the Bivalent mixing valve as a direct result of the oil crisis. The idea was that it would be used in solar energy systems, but it came to be used more in combined systems for heat pumps and boilers powered by electricity or oil.

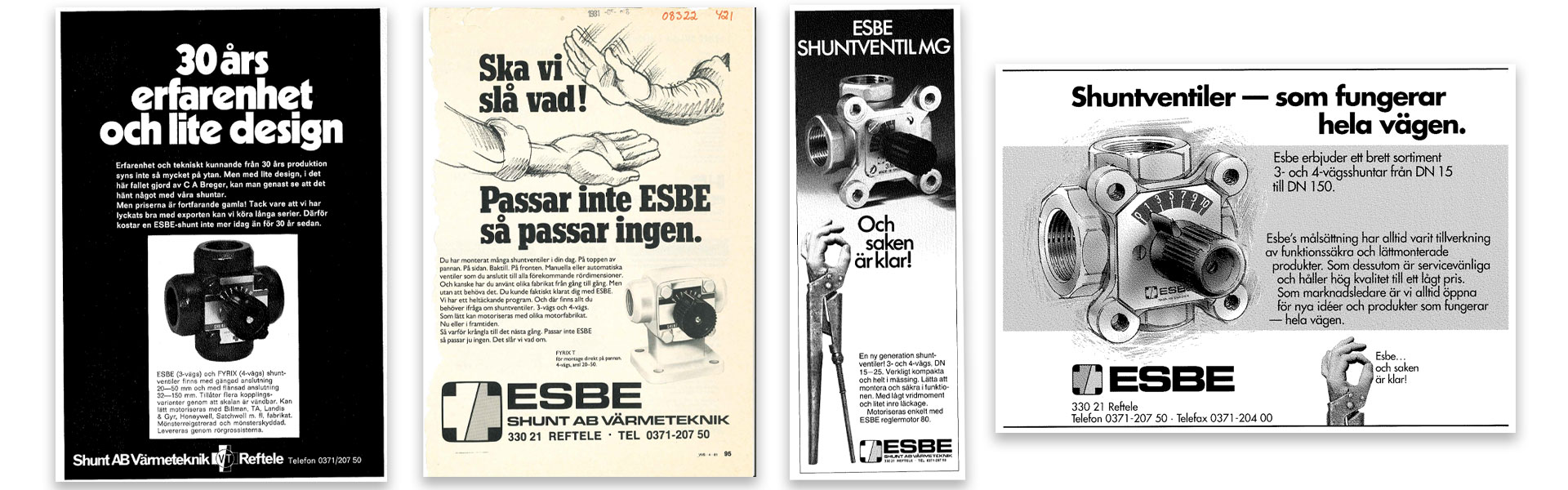

Ads showing ESBE products. From left to right the years 1971, 1981, 1983 and 1994

Waiting time for ESBE’s mixing valves, 1980s

1980 started at rocket speed and ESBE didn’t have time to manufacture mixing valves at sufficient speed. In April, customers had to wait six months for delivery. At the same time, the delivery time for a wood-fired boiler was a whole year. Two years later, the situation was reversed and ESBE decided to increase the export share.

The houses were built more energy-efficiently and this gave opportunities for valves in smaller dimensions. The mixing valve program was therefore expanded with new series of 3- and 4-way valves in brass (MG).

Success for tandem-working MG and M60, 1990s

In the early 1990s, the valve MG series was joined by the actuator M60 series. Working in tandem, they were successful in Europe and contributed strongly to ESBE’s growth. From 2006, the MG and M60 series were replaced by today’s VRG and ARA series respectively.

Actuator series M60 together with valve series MG reaped great success in Europe. The product idea and construction for the M60 series was signed by then CEO Mats Skogsfors. His ideas were visualized by product designer Per Liljeqvist.

ESBE writes new history, the 21st century

Schwedenmischer was said in Germany when talking about mixing valves in general in the 1980s, and if you google it today, you get a hit. We at ESBE are proud of our history and the imprint we have made. We continue to make history. Today, we are the market leader in Europe and offer not only a comprehensive range of rotary valves (commonly referred as mixing valves) but also rotary actuators, thermostatic mixing valves, controllers and much, much more. But that, is a completely different story.

Related articles