ESBE FOCUSES ON ENERGY SAVINGS

2022-12-12

“To assist our customers in providing property owners in Europe with the market’s most resource-efficient products and solutions for regulating heating and cooling in hydronic systems.” This is ESBE’s business concept, and it is fair to say that this is exactly what ESBE does. But how do they do it? All of ESBE’s products are developed and manufactured at the head office in Sweden. We had a chat with Dick Barkman, electricity and property manager at ESBE, about the company’s energy consumption.

What does energy consumption look like at ESBE?

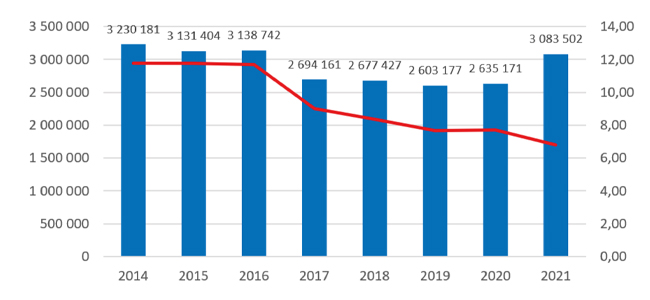

ESBE carried out a major energy survey in 2015, and based on this, we can see that we have radically reduced energy consumption, despite increased production volumes every year. In the graph below taken from the Sustainability Report 2021, we see that electricity consumption increased during 2021, and the reason for this was that production volumes increased significantly.

ESBE AB’s total electrical energy consumption

ESBE AB’s total electrical energy consumption

The blue bars in the diagram show the consumption of electricity, while the red line shows total energy consumption divided by turnover.

Daniel Gustavsson, project manager at Jochnicks Rör, together with the team at Midroc/Granitor, has had a significant role in the work to reduce ESBE’s energy consumption

What has ESBE done to reduce energy consumption?

From 2015 to 2021, we implemented several major initiatives. Above all, I want to highlight the active and positive conversations we’ve had with both Daniel Gustavsson, project manager at Jochnicks Rör, and the team at Midroc/Granitor. These talks and meetings have really been helpful in our efforts to reduce ESBE’s climate footprint. Here are some of the measures ESBE has taken:

• We have invested in a comprehensive control system that provides a good overview when it comes to consumption from production equipment, ventilation, and heating.

• We have replaced the majority of ventilation units with more energy-efficient models

• We have invested in a brand-new compressor plant

• Together with Midroc/Granitor, we carried out a new energy analysis during autumn 2022. The analysis will guide us in our further measures.

|

Energy source |

2015 |

2021 |

Percentage change |

Note |

|

Electricity for heating |

636,000 kWh |

413,000 kWh |

-35% |

Incl. 2,700 sqm extension |

|

Electricity for production |

2,495,000 kWh |

2,670,000 kWh |

+7% |

Turnover for ESBE AB has increased by 71% |

|

Oil for heating |

24.8 cu m |

9.1 c um (≈92 000 kWh) |

-65% |

The boiler is only used for auxiliary heat |

So for the 2021 extension, did you think about the energy consumption a little more?

Yes, for sure. Together with Daniel at Jochnicks Rör, we delved into the planning of our energy consumption. We built a new boiler plant. This center supplies the extension, but also large parts of the existing assembly halls. We had to give this a little extra thought, because old technology would meet new. With the help of control valves, a customised system was created that prioritises the new boiler center over the older one, which will remain in operation.

We invested in a battery of six heat pumps (air/water) that can be increased to ten, if necessary. If we need to extend the building again, for example.

The dimensions of the compressed air system were increased, and a new pressure equalisation tank was installed in connection with the extension. This was done to avoid the need for another compressor (we have three).

When the roof was put on the extension, we installed solar panels, which we estimate can contribute approximately 128,000 kWh per year. Feel free to read the previously published article about ESBE's 700 sqm. solar panels.

While we’re on the subject of solar panels – what does ESBE think about renewable electricity?

ESBE takes everything to do with sustainability and energy consumption work very seriously. Some issues cannot be compromised on, and sustainability is one such issue. For the factory in Reftele, we only buy renewable electricity. In addition to the investment in solar panels, ESBE is also a partner in a wind power company, and together with the solar energy, this means that we have a wholly-owned electricity supply that corresponds to approximately half of our total energy needs.

What I didn’t mention earlier is that in 2023, we will replace the small amount of heating oil we use with the renewable fuel, HVO, which is part of ESBE’s long-term energy plan for fossil-free heating of the premises by 2025.

Electricity and property manager Dick Barkman has been responsible for the optimizing of ESBE’s energy consumption

What does the long-term sustainability work look like for the years to come?

Although it’s satisfying to see that ESBE is steadily reducing its demand for energy, we are not content. There is always improvement work to be done, and first on the agenda is changing older lighting fixtures to LED. The change will take place at almost all production premises, and is expected to be done by midsummer. Changing the lighting will reduce electricity consumption by approximately 8 percent compared to our total annual consumption in 2022.

Brilliant! Thank you, Dick.

Related articles

ESBE products are important in energy conversion »

ESBE CRx decreases energy consumption »

How sustainable and environmentally friendly is ESBE's valve series VRG?

Sustainability is a natural part of ESBE's DNA »