FAQ THERMOSTATIC MIXING VALVES

Below we have answered frequently asked questions from our customers. If you do not find your answers here please contact your closest wholesaler or ESBE Sales company in your country.

Why is it important to have a thermostatic mixing valve?

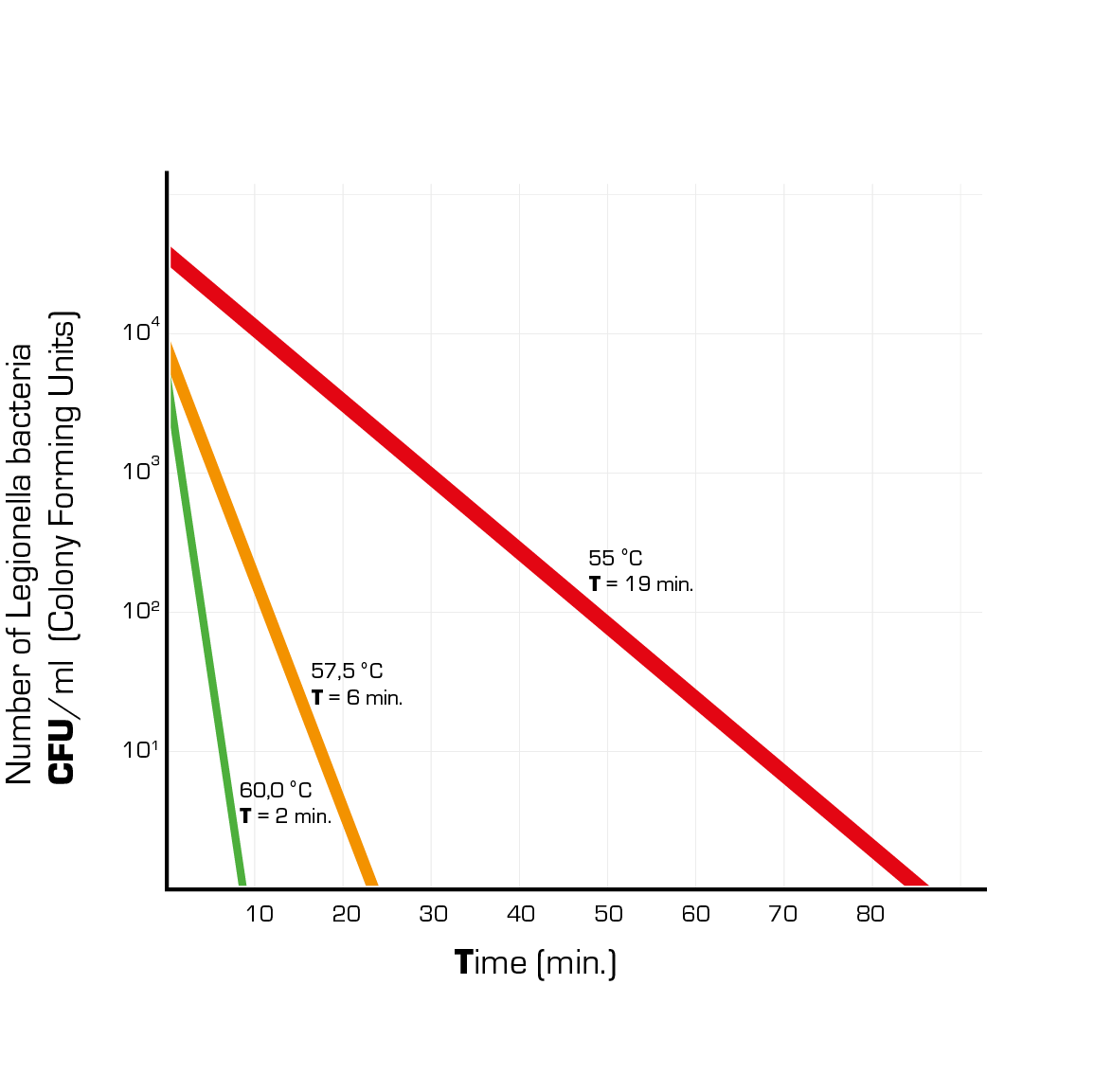

You need to reduce the water temperature to prevent scalding.... but at temperatures below 60ºC, there is risk of legionella bacteria growth

- It takes 1,5–2 minutes to achieve a scalding injury in 52°C hot water.

- At 57°C it takes 10 seconds to get scalding injuries.

- 60°C hot water gives scalding injuries of third degree in less than 3 seconds.

What does the numbers 1…6 on the knob stand for?

The 1…6 marking on the knob is an indication of mixing temperature setting steps of the valves temperature range. The temperature step between every setting is approximately 4°C / 5°C.

However, to set the mixing temperature in accurate way we need to secure flow volume above 4l/min for VTA300 series, and above 9l/min for VTA500 series, and measure the temperature in a point of use for more than 60s.

Please see the installation manual for more information.

What thermostatic valve should I use? I have installation size DN25.

The valves should be selected based on the needed water flow, application area and system conditions, not by pipe size.

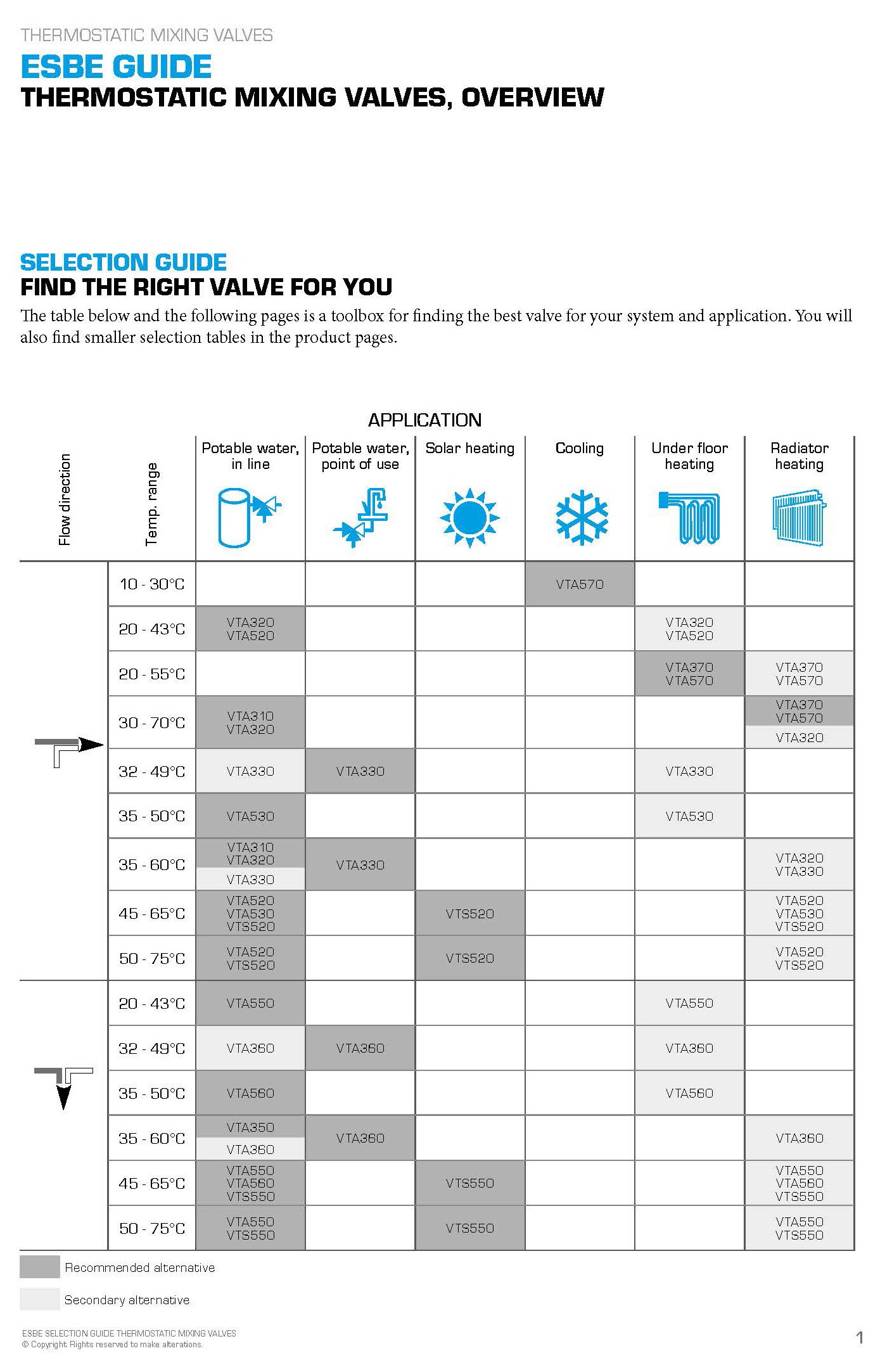

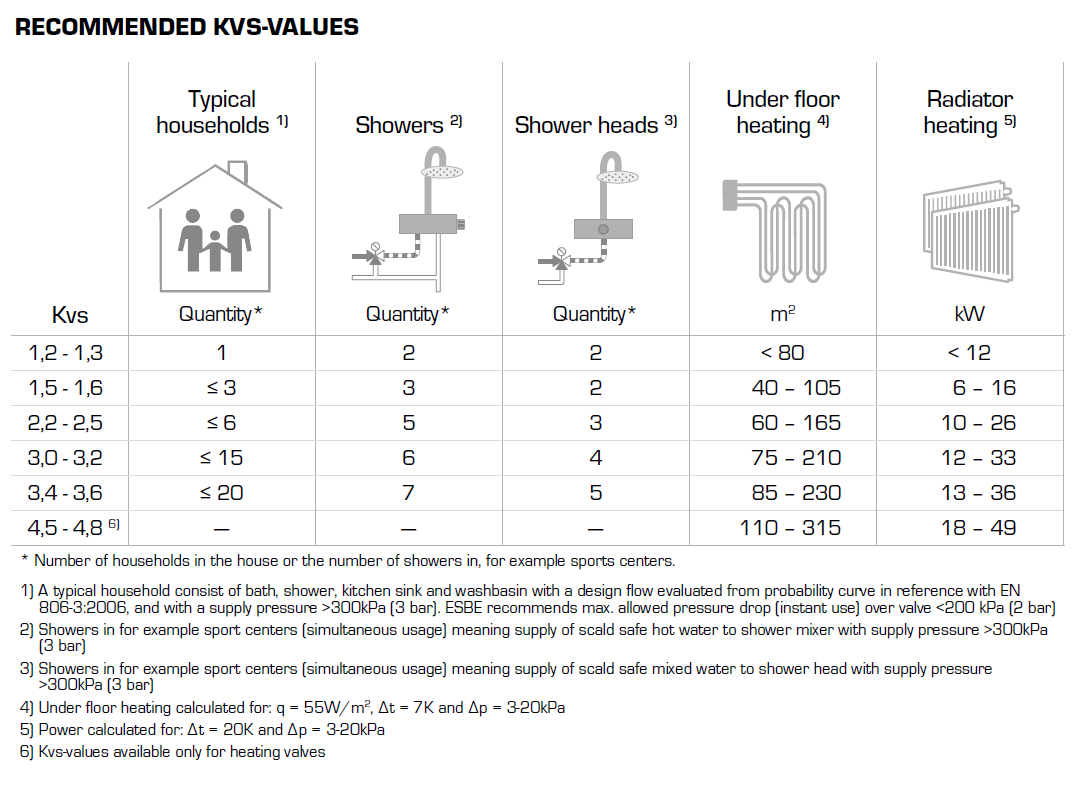

ESBE has created quick guides to make selection easier, and below you can find two different tables.

First table speaks about the application area,

and the second one about the Kvs value in several applications under specific conditions.

For more information please contact customer service.

Which thermostatic mixing valve should I choose for a system with hot water circulation (HWC)?

ESBE has a product for systems with hot water circulation called VTR300, more information is available on the product page.

You can also use VTA320 or VTA520, depending on the flow capacity needed. You should never use a VTA310 in this type of applications.

Thermostatic mixer is very quick logged with lime.

Make sure that the installation is made with a heat trap. Please see article that describe heat traps more in detail.

Can the VTS500 also be assemled into the supply line?

Yes under the conditions according to the product specification.

Can a thermostatic mixing valve also be used as a diverting valve?

The VTD300 is a thermostatic diverting valve developed for these applications. You should not use a VTA300. If you need higher flow capacity the VTA500 series can be used as a diverting valve.

The thermostatic mixing valve VTA / VTS provide inconsistent mixing temperature!

To get the right tap temperature you need:

- A minimum flow volume 4 l/min for all VTA300, and 9 l/min for all VTA500 series.

- A minimum temperature change ∆t of 10°C between the hot water supply and the set mixing temperature.

Please see Datasheet for more information.

What happened if the cold water pressure drops?

The valve will also reduce or close the hot water supply to ensure the set mixing temperature. (VTA310 will not be able to close completely)

What happens if the cold water inlet temperature is higher as the adjusted temperature?

The mixing temperature can never be lower than the cold water inlet temperature. (VTA310 risk for increased temperature)

What is VTF320?

The VTF320 is a 2-way thermostatic flow limitation valve dedicated for potable hot water circulation systems.

What does ‘’flow limitation valve’’ mean?

The VTF320 is a thermostatic valve which limits the flow in a potable hot water circulation system depending on the water temperature. When the potable hot circulation water temperature increases the VTF320 will start to close, which will result in flow reduction. If the temperature exceeds 55°C the valve will close, and flow of PHW-C will stop.

How can VTF320 reduce cost and energy usage and optimize the system?

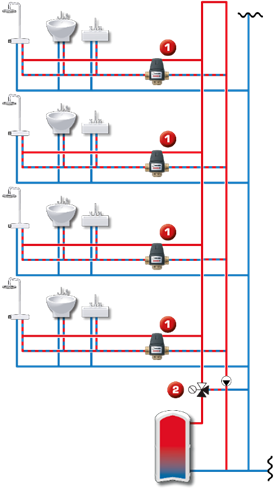

The optimization of the system is connected to the energy and cost savings. If we have several zones with PHW-C we can, thanks to VTF320, have control over the zones. In practice it means that if one of the zones has reached temperature of PHW-C it will be shut off, while the other ones which have not reached the correct temperature will continue to be heated until they reach a temperature above 55°C. No high temperature water flow means no heat loses, which means no warm water preparation is needed, this is valid for shutting off the zones. By not heating the zones which already reached the target of PHW-C we decrease the energy needed for the circulation pump, heat loses, PHW preparation. This optimization of the system generates savings!

How can I preform thermal disinfection against legionella when it is a thermic valve?

In case of thermal disinfection, the system needs to be flushed and heated above 70°C to the tap. To achieve this the tap needs to be opened. The biggest risk of legionella growth is in “blank” spots where the water is not moving and in tanks where the water is standing still for a longer time and have lower temperatures. In circulation pipes water is moved much more frequently compared to the potable water pipes/tanks, and at the same time the goal is to keep the water on certain temperature level. Legionella growth is low when temperatures of the PHW are kept high and the water is moved. The chart below shows how quickly legionella dies in relation to the temperature and time:

What is the benefit of using the VTF320?

The benefits are system optimization and reduction of energy usage as well cost reduction.