FAQ CIRCULATION UNITS

Below we have answered frequently asked questions from our customers. If you do not find your answers here please contact your closest wholesaler or ESBE Sales company in your country.

Where and in which applications can I use the Double Circulation unit?

The double circulation unit can be use in any application and with any heating source.

For applications examples please check the data sheet of the product.

How does the manifold/manifold with hydraulic separation works and why do I need it?

The manifold used in the Double Circulation Units is a hydraulic block with the function of a standard manifold or a manifold with hydraulic separation. To enable or disable one of the options simply turn the screw. The open bypass means that a certain amount of the flow will be sent back to the heat source – this option is required when heating source has its own pump or in case where there is a system pump outside the heating source (primary side of double circulation unit). The close bypass means that there is no flow which is sent back to the heating source, the flow is divided based on the flow capacity of the double circulation unit pumps. The pumps capacity is set to the current demand of each heating circuit. This option is required in applications where heating source do not have built in circulation pump or there is no system pump outside the heating source (primary side of double circulation unit).

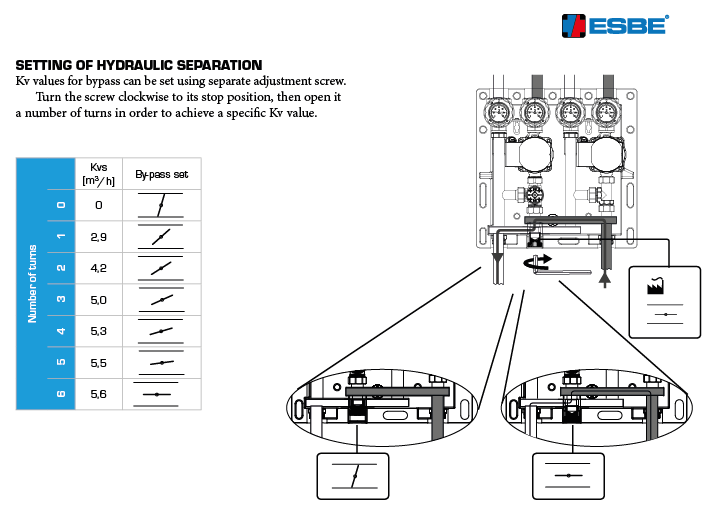

The bypass can be set on a desired value. This means that instead of having open/close position we can choose a value to balance the system if needed. See below:

What is the right position of installation of the double circulation unit?

The double circulation unit can be placed above, under and beside the heating source. The units can be rotated 360°. For more information please check the manual or data sheet of the product.

Is the hydraulic separation option in manifold of double circulation units just on/off function and how to set it?

The bypass function and its value can be chosen by right number of turnings of the screw.

See the point ‘’How does the manifold/manifold with hydraulic separation works and why do I need it?’’

What type of valves are used in the Double Circulation Unit?

In the Double Circulation Unit we are using ESBE’s rotating valves with progressive characteristic with the value of kvs 8. This combination of kvs and progressive characteristic gives the most universal performance no matter what application and heating source you are working with.

What type of actuator is used in Double Circulation Unit?

We are using ESBE’s 3-point 120s 230VAC actuator – ARA661 with a QuickFIT connector. 3-point signal is the most common control signal delivered by heat source manufacture. In case of the need for a different control signal please contact our customers service.

Which type of pump is used in the double circulation unit?

The double circulation unit comes with Wilo PARA 15/8-75/SC 130mm. For settings of the pump please check the manual of the product or circulation pump. For the available pressure of the unit please check the data sheet of the product.

Can the double circulation unit be upgraded?

The double circulation unit DDA111 (group with a direct and mixing supply) can be upgraded to the DAA111 (group with two mixing supplies) by using an upgrade kit DVA111 (art. no. 62100300).

The units can be downgraded to direct by changing the valve to a plug set and insulation shell cover (delivered on demand) – in case this is need please contact our customer service.

Can I use a different ESBE actuator or controller on Double Circulation Unit?

Yes, in the case where you need to use one of our CRx products or ARA with a different control signal please contact our customers service.

Do I need additional accessories such as manifold or hydraulic separation to Double Circulation unit?

No, the unit is equipped with all devices. Using a ESBE’s Double Circulation Unit you will receive a finished product equipped with ball valves, thermometers, high efficient pumps, valves and actuators (depending from version one or two) and a manifold with a bypass function, which by the simple rotation of the screw, the option of standard manifold or manifold with hydraulic separation will be enabled.