Manifold

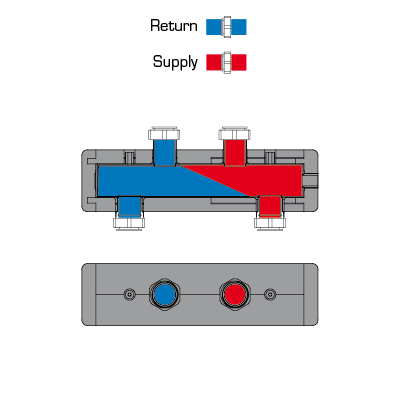

GMA400, GMA500

- Pressue class PN6

- Thermal separation for more efficient system performance

- Colour coding for easy and quick product installation

- GMA410 and GMA500 has a possibility to connect a safety group or flow sensor

Serie GMA410 is a hydraulic separation to separate heating circuit from heating source. Series GMA420/430/440/450 are manifolds for circulation units. The manifolds are available for 2, 3 and on request for 4 and 5 heating circuits.

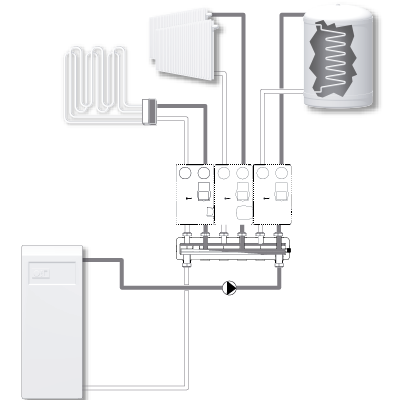

Series GMA500 are manifolds with integrated hydraulic separation for 2 and 3 heating circuits.

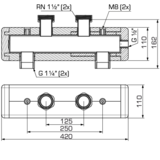

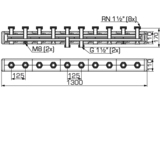

GMA411, Hydraulic separation for 1 unit

| Art.no. | Reference | No. of circulation units | Connections to system | Connections from heat source | with hydraulic separator | Weight [kg] |

| 66001100 | GMA411 | 1 | RN 1½" | G 1½" | Yes | 4,3 |

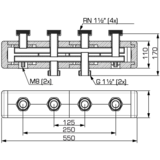

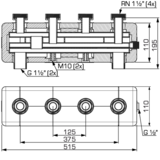

GMA421, for 2 units

| Art.no. | Reference | No. of circulation units | Connections to system | Connections from heat source | with hydraulic separator | Weight [kg] |

| 66001200 | GMA421 | 2 | RN 1½" | G 1½" | No | 5,3 |

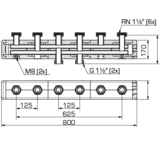

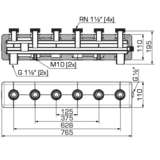

GMA431, for 3 units

| Art.no. | Reference | No. of circulation units | Connections to system | Connections from heat source | with hydraulic separator | Weight [kg] |

| 66001300 | GMA431 | 3 | RN 1½" | G 1½" | No | 7,2 |

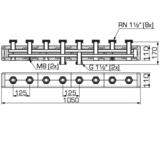

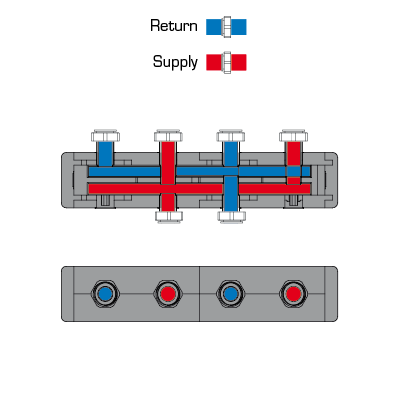

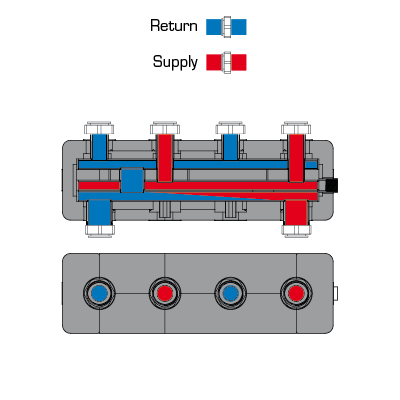

GMA441, for 4 units

| Art.no. | Reference | No. of circulation units | Connections to system | Connections from heat source | with hydraulic separator | Note |

| 66001400 | GMA441 | 4 | RN 1½" | G 1½" | No | Products on request have a longer lead time; in order to know the delivery time please contact our customer service for more information |

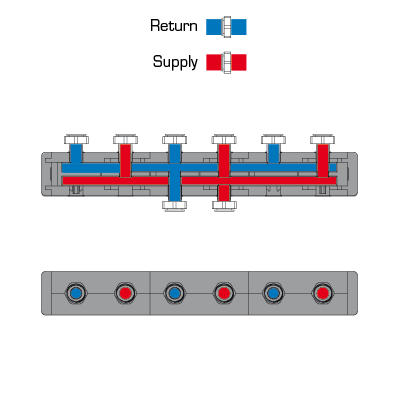

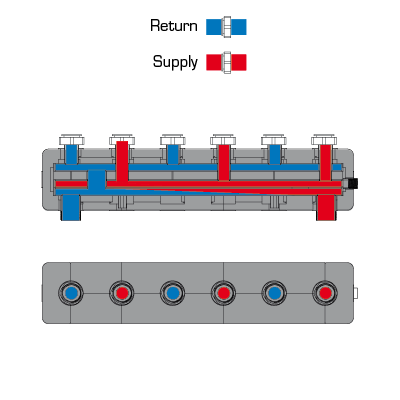

GMA451, for 5 units

| Art.no. | Reference | No. of circulation units | Connections to system | Connections from heat source | with hydraulic separator | Note |

| 66001500 | GMA451 | 5 | RN 1½" | G 1½" | No | Products on request have a longer lead time; in order to know the delivery time please contact our customer service for more information |

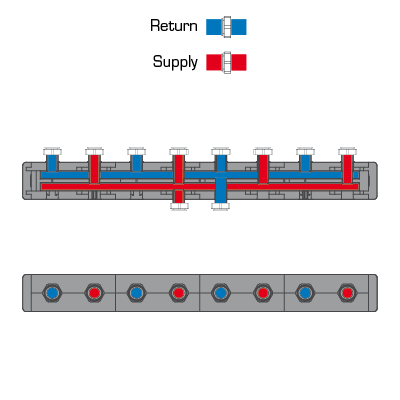

GMA521, for 2 units with integrated hydraulic separator function

| Art.no. | Reference | No. of circulation units | Connections to system | Connections from heat source | with hydraulic separator | Weight [kg] |

| 66001600 | GMA521 | 2 | RN 1½" | G 1½" | Yes | 8,2 |

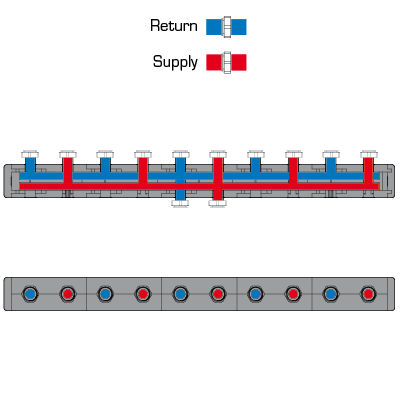

GMA531, for 3 units with integrated hydraulic separator function

| Art.no. | Reference | No. of circulation units | Connections to system | Connections from heat source | with hydraulic separator | Weight [kg] |

| 66001700 | GMA531 | 3 | RN 1½" | G 1½" | Yes | 11,1 |

Operation

Installation examples

Documents

| Name | Download |

| Installation instruction GMAx00 |

|

Technical data

| Pressure class: | PN 6 |

| Working pressure: | 0,6 MPa |

| Standard outlet spacing: | 125 mm |

| Flow rate: | see data sheet |

| Insulation: | EPP λ 0,036 W/mK |

| Media temperature, max.: | +110 °C |

| Media temperature, min.: | 0 °C |

| Material, in contact with water | Components: Black coated steel S235 |

Conformity

SI 2016 No. 1105

Dimensioning

Download area

| Type | Preview | Download |

| Data sheet | GMA400, GMA500 |

|

| Installation instruction | GMAx00 |

|

| Certificate | Declaration of Conformity, GMAx00 |

|

| Certificate | Declaration of Conformity UKCA, GMAx00 |

|

| Certificate | Building Product Declaration BPD3, GMA400/GMA500 |

|

| Certificate | EAC certificate (RU), GMA400/GMA500 |

|

| Certificate | Certificate of conformity UA, GMA400/GMA500 |

|

| Image | GMA411, high res |

|

| Image | GMA421, high res |

|

| Image | GMA431, high res |

|

| Image | GMA441, high res |

|

| Image | GMA451, high res |

|

| Image | GMA521, high res |

|

| Image | GMA531, high res |

|

| 2D Image | GMA411 |

|

| 2D Image | GMA421 |

|

| 2D Image | GMA431 |

|

| 2D Image | GMA441 |

|

| 2D Image | GMA451 |

|

| 2D Image | GMA521 |

|

| 2D Image | GMA531 |

|

| 3D drawing (stp file) | GMA411 |

|

| 3D drawing (stp file) | GMA421 |

|

| 3D drawing (stp file) | GMA431 |

|

| 3D drawing (stp file) | GMA441 |

|

| 3D drawing (stp file) | GMA451 |

|

| 3D drawing (stp file) | GMA521 |

|

| 3D drawing (stp file) | GMA531 |

|

Applications

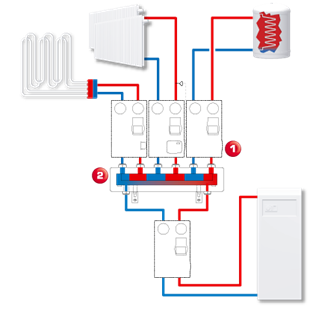

Circulation unit to optimize energy transportation in domestic hot water application.

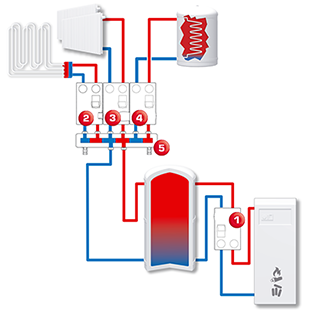

Return temperature unit designed for solid fuel applications, where a return temperature control is required.

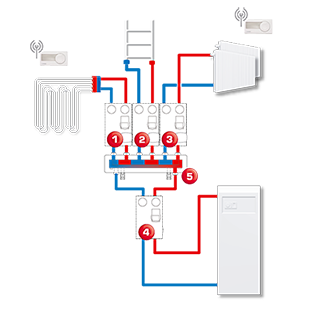

Heat pump application with Circulation units designed for heating circuits where control by weather or indoor / outdoor temperature and pump control is required.

Return temperature unit designed for solid fuel applications, where a return temperature control is required.

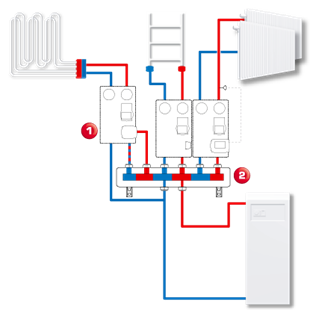

Circulation unit with bivalent valve together with actuator for under floor heating control.