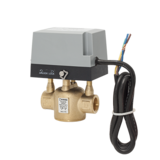

Motorized ball valve

MBA130

- Air bubble tight

- Auxiliary switch included

- Anti-condensation resistor to prevent condensation

- Flexible and easy to install

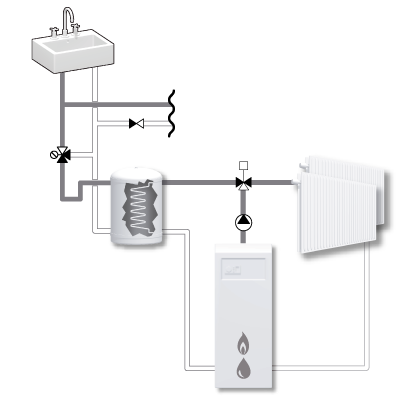

Series MBA130 is a range of 3-way motorized ball valves with actuator for use in heating and cooling system. The valve is air bubble tight according to EN12266-1. The MBA130 series is available in DN20-25 and comes with different type of connections to suit most needs. The actuator is assembled on the ball valve with a metallic spigot that allows to assembly/disassembly the actuator in a secure , simple and rapid way.

Product range

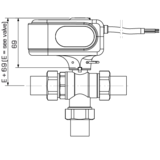

MBA132, External thread

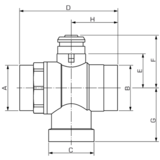

| Art.no. | Reference | DN | Kvs | Connection A | Connection B | Connection C | D [mm] | E [mm] | F [mm] | G [mm] | H [mm] | Weight [kg] |

| 43102500 | MBA132 | 20 | 9,6 | G 1" | G 1" | G 1" | 72 | 25 | 39 | 39 | 34 | 0,76 |

| 43102600 | MBA132 | 25 | 11,3 | G 1¼” | G 1¼” | G 1¼” | 82 | 29 | 43 | 42 | 40 | 0,99 |

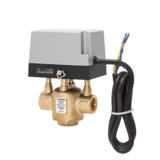

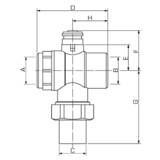

MBA132, External thread with adapters

| Art.no. | Reference | DN | Kvs | Connection A | Connection B | Connection C | D [mm] | E [mm] | F [mm] | G [mm] | H [mm] | Weight [kg] |

| 43102700 | MBA132 | 20 | 9,6 | G ¾" | G ¾" | G ¾" | 134 | 25 | 38,5 | 70 | 65 | 1,07 |

| 43102800 | MBA132 | 25 | 11,3 | G 1" | G 1" | G 1" | 149 | 29 | 42,5 | 75,5 | 73 | 1,46 |

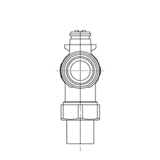

MBA135, Internal, internal and external thread

| Art.no. | Reference | DN | Kvs | Connection A | Connection B | Connection C | D [mm] | E [mm] | F [mm] | G [mm] | H [mm] | Weight [kg] | Note |

| 43102100 | MBA135 | 20 | 9,6 | G ¾” | G ¾” | G ¾” | 68 | 25 | 39 | 70 | 34 | 0,87 | Connection A, B = Internal thread; Connection C = External thread |

| 43102200 | MBA135 | 25 | 11,3 | G 1” | G 1” | G 1” | 81 | 29 | 43 | 76 | 41 | 1,14 | Connection A, B = Internal thread; Connection C = External thread |

Technical data

Technical data

| Pressure class: | PN 32 |

| Working pressure: | 3,2 MPa |

| Torque (at nominal pressure): | < 4 Nm |

| Leakrate: | EN 12266-1: internal leakage rate B, Air bubble tight; EN 12266-1: external leakage rate A, Air bubble tight |

| Power supply: | 230 ± 10% V AC, 50 Hz |

| Power consumption: | Motor operation: 3,5 W; Anti condensation resistor: up to 5 W |

| Control signal: | 2-point SPST (Singel Pole Single Throw) |

| Enclosure rating: | IP44 |

| Protection class: | II |

| Running time 90°: | 40 s |

| Rating auxiliary switch: | 6(1) A 230 V AC |

| Torque: | 10 Nm |

| Media, Heating water: | in accordance with VDI2035 |

| Media, Water/Glycol mixtures: | max. 50 % (above 20% admixture, the pump data must be checked) |

| Media temperature, max.: | +90 °C |

| Media temperature, min.: | 0 °C |

| Ambient temperature, max.: | +50 °C |

| Ambient temperature, min.: | 0 °C |

| Connections, Internal thread (G): | ISO 228/1 |

| Connections, External thread (G): | ISO 228/1 |

| Material, Valve body: | Brass CW 617N, Nickel plated |

| Material, Body end: | Brass CW 617N, Nickel plated |

| Material, Seat: | PTFE |

| Material, O-ring: | FPM |

| Material, Ball: | Brass CW 617N, Chrome plated |

| Material, Washer: | PTFE |

| Material, Shaft: | Brass CW 614N, Chrome plated |

| Material, O-ring, shaft: | HNBR |

| Material, Gasket: | Heat resistance fibre |

| Material, Union: | Brass CW 617N, Nickel plated |

| Material, Nut: | Brass CW 617N, Nickel plated |

Conformity

SI 2016 No. 1105 (UK)

EMC 2014/30/EU

RoHS3 2015/863/EU

SI 2016 No. 1091

SI 2012 No. 3032

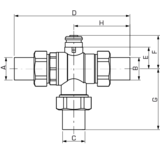

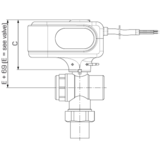

Dimensioning

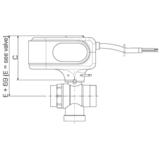

Wiring

Download area

Download area

| Type | Preview | Download |

| Data Sheet | MBA130 |

|

| Installation instruction | MBA120/MBA130 |

|

| Certificate | Declaration of Conformity, MBA100 |

|

| Certificate | Declaration of Conformity UKCA, MBA130 |

|

| Certificate | EAC certificate (RU), MBA130 230V |

|

| Certificate | UKRSEPRO certificate (UA), MBA130 |

|

| Approval | PZH-certificate (PL), MBA130 |

|

| Image | MBA132, external thread, high res |

|

| Image | MBA132, external thread with adapter, high res |

|

| Image | MBA135, internal, internal and external thread, high res |

|

| 2D Image | MBA132 |

|

| 2D Image | MBA132 with adapter |

|

| 2D Image | MBA135 |

|

| 3D drawing (stp file) | MBA132, DN20 |

|

| 3D drawing (stp file) | MBA132, DN25 |

|

Quick links

Quick links

| ESBE Hydronic selection |

| ESBE Catalogue Online |